Textile industry application case

描述

Company Profile

After 40 years of development, a group has gradually established its main business in branded clothing, and has also been involved in real estate development, financial investment and other fields. It is a large multinational group company with diversified development and professional development. Ranked among the top 2000 global enterprises in Forbes in 2021, the top 100 private enterprises in Zhejiang Province in 2021, the top 500 private enterprises in China in 2021, and the top 100 enterprises in Zhejiang Province in 2021, it is the most expensive trademark in Ningbo.

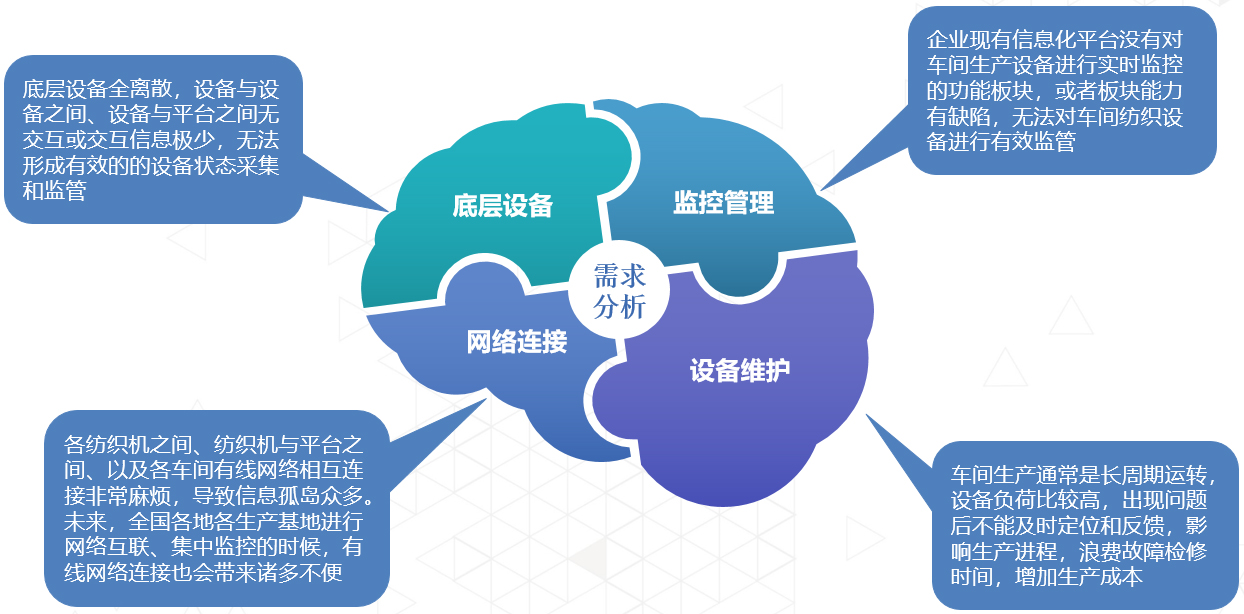

Apparel Industry Demand Analysis

As the largest garment manufacturer in China, the company constantly uses high-tech and advanced equipment to upgrade its industrial base and improve product quality. It has successively adopted the "starch-free process" to develop "HP cotton non-iron shirt" and "VP cotton non-iron shirt", filling the domestic market and technical gaps, and has won five awards from the Ministry of Science and Technology, the Ministry of Foreign Trade and Economic Cooperation, the Quality Supervision Bureau and the State Environmental Protection Administration It was awarded the title of "National Key New Product" jointly by ministries and commissions. The company's technology center was recognized as a national technology center by the National Development and Reform Commission, the Ministry of Finance, the Customs and the State Administration of Taxation. In 2004, Youngor Group was rated as "China's Informatization Benchmarking Enterprise" and "China's Top 100 Informatization Enterprises".

Driven by the goal of "creating an international brand", the company not only keeps improving in clothing manufacturing, but also hopes to continue to seek development and improvement in manufacturing technology and digital and intelligent development. However, the overall intelligence level still needs to be improved, and the specific problems are concentrated in:

It is worth noting that the data collection in the textile industry is recognized as a "blind box" in the industry, which has great technical difficulties, and the "private" protocol brings great resistance to the network data collection of equipment.

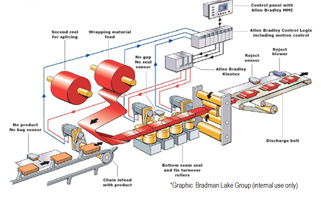

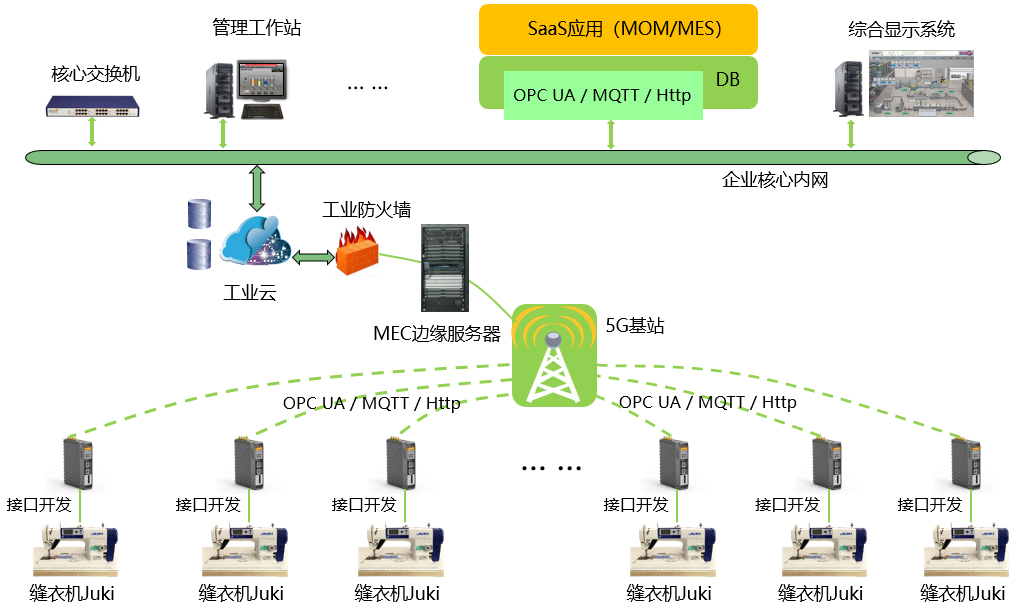

5G data acquisition system architecture diagram of textile industry

The key equipment in the industrial information data acquisition system includes but is not limited to: terminal textile machine, JENET 5G intelligent industrial gateway, 5G base station, MEC edge server/UPF, firewall, cloud platform/IDC/data server, NMS gateway management system, Manage workstations, large-screen servers, and integrated displays. The system architecture is shown in the following figure:

In the above picture, the data collection between Juki clothing machine and industrial gateway needs to be realized through specific interface development. The data is sent to the platform SaaS management software through OPC UA/MQTT/Http and other transmission protocols. After system analysis, Presented on the integrated display.

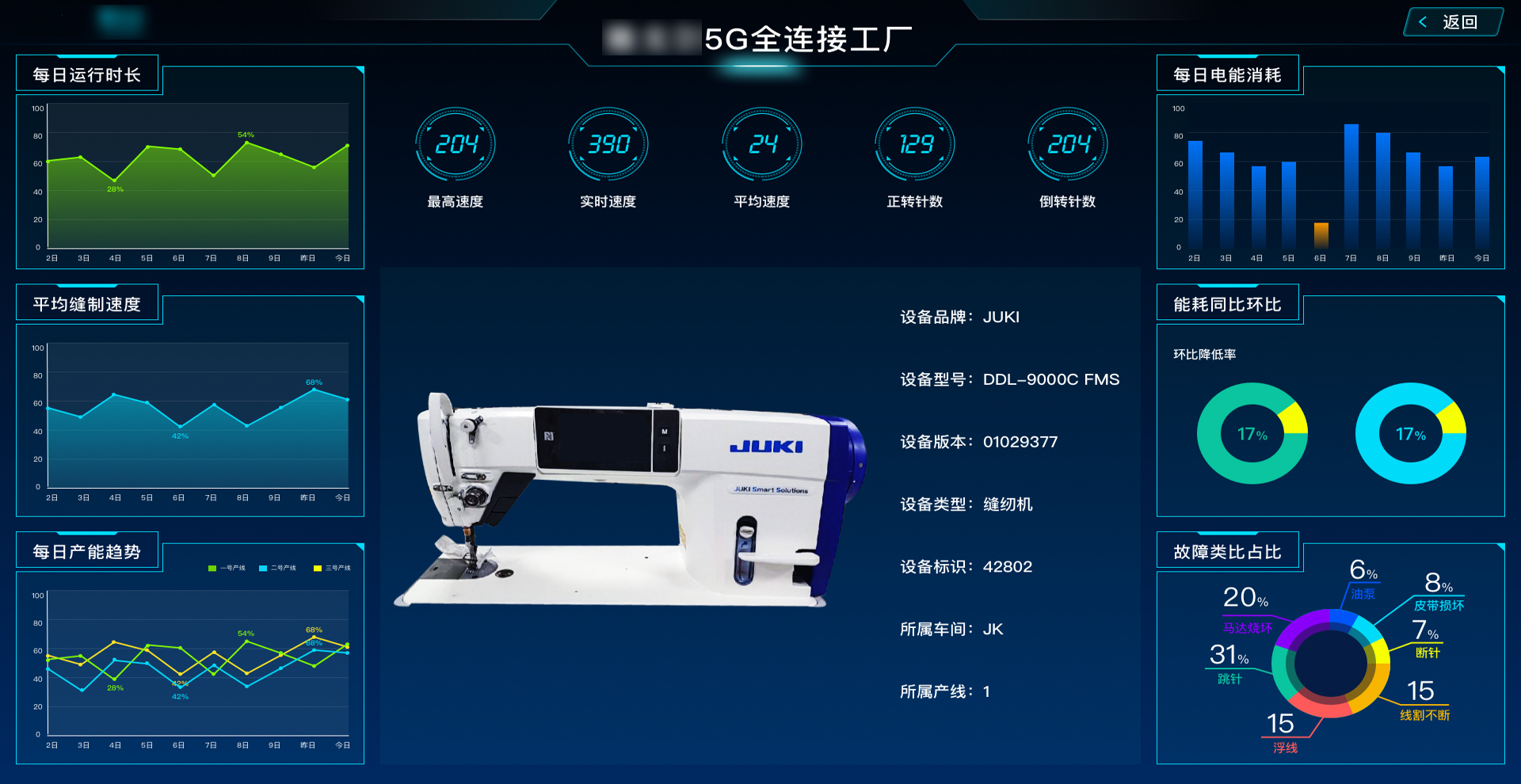

Device management for SaaS layer application presentation

In terms of platform presentation, relying on the underlying data collection and systematic analysis based on equipment status information, the overall presentation of equipment point inspection information, fault information, and equipment operation-related parameters provides an intuitive visual picture for background monitoring. The overall system diagram is as follows:

System functions

▶ Gateway southbound communication protocol: support access to various mainstream protocols, and directional development of some specified protocols;

▶ Data collection: support the data collection of the protocol adaptation device and transmit it in 5G mode;

▶ Gateway northbound communication protocol: support OPC UA/MQTT/Http and other transmission protocols to upload data to the platform system;

▶ Log recording: support the recording of historical data, historical alarm information, device online and offline and other data information of the device;

▶ Terminal device management: support adding, configuring and creating files for gateways and connected devices through the Web and management platform;

▶ Equipment monitoring: 24-hour uninterrupted monitoring of the operation status and production information of each equipment in the workshop by monitoring the large screen;

▶ Fault alarm: support equipment fault alarm, and push it to relevant personnel on the platform or through the mobile terminal;

▶ User management: Supports user classification and role-based management in the system.

Achieve goals or solve problems

▶ The JENET 5G intelligent industrial gateway has the ability to resist strong magnetic interference, adapt to wide temperature conditions of -40~85℃, and has a full industrial-grade body design, which can adapt to the needs of complex and changeable working environments;

▶ Supports multi-industrial protocol analysis, supports customized development of specific protocols, supports point-to-point data transfer between different brands and different protocols, and perfectly solves the difficulty of data acquisition in industrial scenarios;

▶ Real-time data transmission through 5G wireless network, convenient networking, monitoring platform can remotely monitor the operating status of equipment, no need for on-site inspections, and eliminate information islands;

▶ Quickly respond to equipment maintenance in fault state, improve efficiency, increase production capacity, etc.

Contact Us

Building 6, Ningxing Jiali Plaza, No. 185 Mingxin Road, Yinzhou District, Ningbo City

Tel:( 86-574 ) 87861201

Fax:( 86-574 ) 87861200

Official Account

WeChat Channel

© 2021 JETRON Powered by www.300.cn SEO