Application case of a tire industry

描述

1. Project Background

The 3 million high-performance intelligent all-steel radial tire project in the third phase of a tire Zhazuo is expected to have a total investment of 2.16 billion yuan, a total land area of 248 mu, and a total construction area of 170,000 square meters. After completion and production, it is expected to achieve annual sales revenue. About 3 billion yuan. The project will make full use of big data and information technology to realize intelligent production, less labor and green operation, and comprehensively build an industry-leading green smart factory based on the industrial Internet platform.

The project plans to purchase a part of brand-new equipment and recycle part of the old equipment. The old and new equipment are mixed, the technological process is complex, and the automation and intelligence requirements are high. If the traditional manufacturing mode of component procurement, assembly, installation, programming, and debugging is signed separately, the customer's construction period and quality requirements cannot be met. At the same time, as a 5G pilot project in Guizhou Province, the project needs to complete the 5G network interconnection between the equipment of the whole plant.

2. Solutions

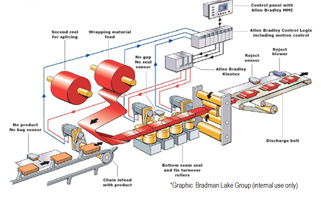

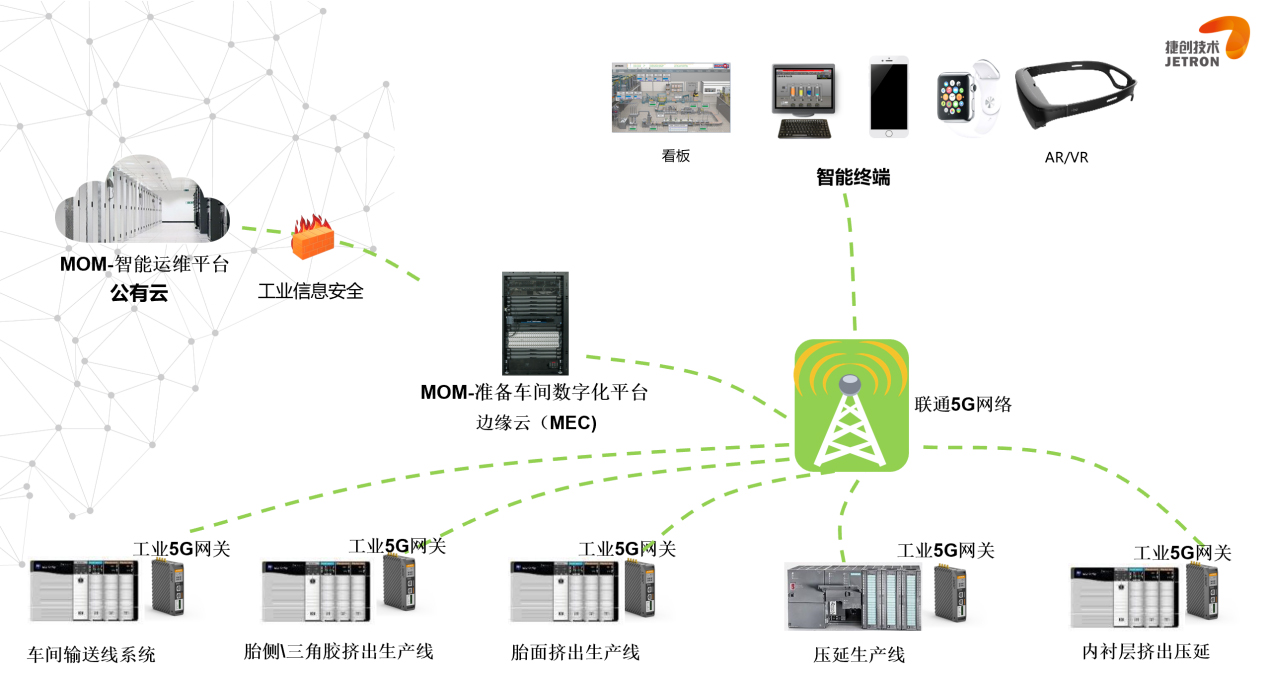

Jie Chuang Technology has undertaken the turnkey turnkey project of the three-composite sidewall extrusion line, the three-composite extrusion tread production line, and the three-composite extrusion apex rubber hot-tie production line, and completed the project from design, complete set, installation, programming , debugging, and all the work of ensuring production; the automation control system of the entire project adopts Rockwell's LOGIX platform, PLC, inverter, servo, and HMI to realize real-time monitoring of data and status; the network system of the whole plant adopts JENET 5G gateway, Realize the interconnection of the whole plant equipment

3. Project value

Our company has realized the transformation from component supplier---complete set supplier---solution provider, and has the ability and strength of three electricity general contractors in each process section of the tire industry, which saves the project implementation time and improves the device performance. At the same time, it helped customers realize the integration of equipment control automation, 5G network, and data informatization, realizing the interconnection and interoperability of equipment in the whole plant, and truly realizing the intelligent factory.

Contact Us

Building 6, Ningxing Jiali Plaza, No. 185 Mingxin Road, Yinzhou District, Ningbo City

Tel:( 86-574 ) 87861201

Fax:( 86-574 ) 87861200

Official Account

WeChat Channel

© 2021 JETRON Powered by www.300.cn SEO