Industry Capability

According to the business characteristics of various industries, we create personalized industry solutions and provide users with one-stop products and services.

Industry Capability

Related cases

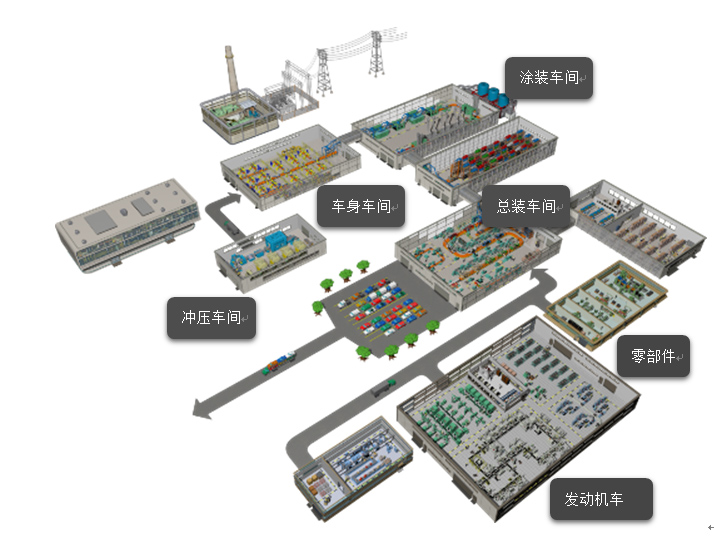

Automobile industry

1、Overview of the automotive industry

JETRON focuses on providing automation and information integration solutions for the automobile manufacturing industry, including control system planning, design, panel integration, on-site programming and debugging, as well as consulting, development and deployment of various customized information systems.

l Engine workshop application scheme

n Engine shop challenges

u Shorter product life cycle

u Wide variety of product types

u Production process quality assurance and data collection

u The device interface is complex and numerous

n solution

u Control standards based on various control system architectures

u Flexible production line based on recipe management

u Engine manufacturing MES system

u Device integration of standard Ethernet

n Challenges of new energy battery workshop

u Establishment of new processes and new standards

u Cell quality tracking and traceability

u The device interface is complex and diverse

n solution

u TESLA/GM standard

u New energy battery assembly MES system

u Industrial Ethernet applications based on standard Ethernet

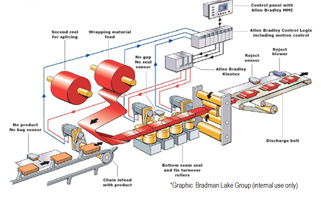

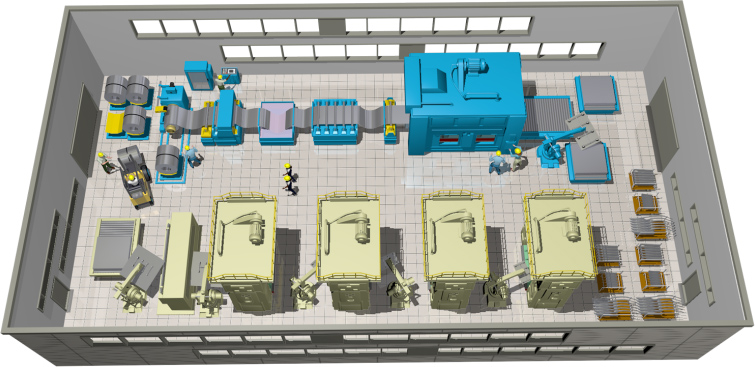

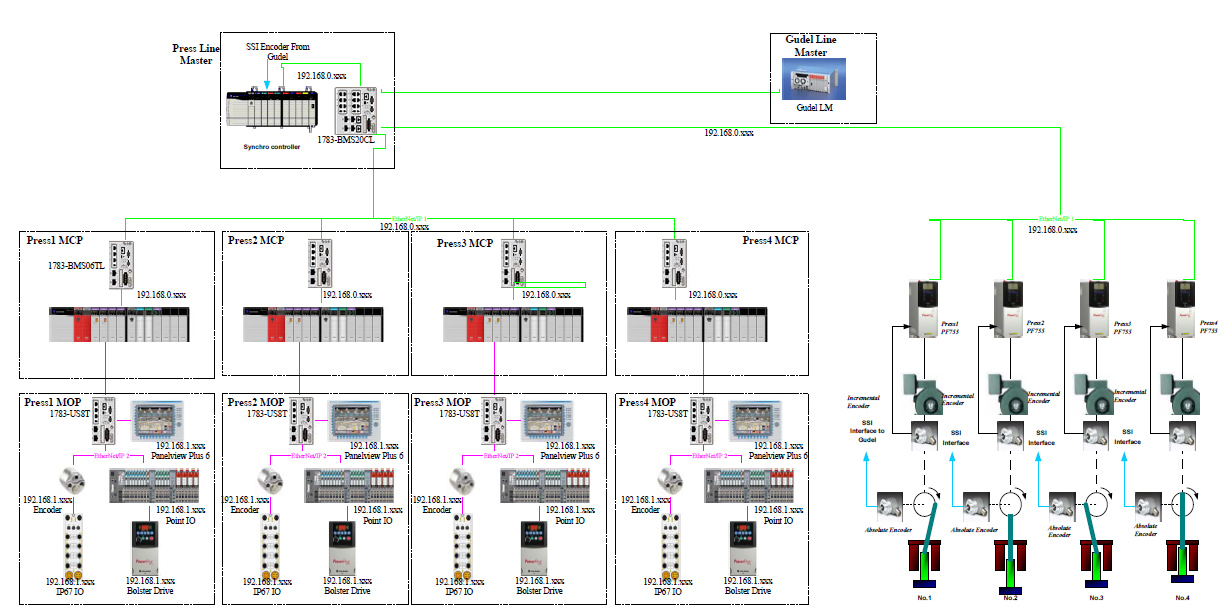

l Application scheme of stamping workshop

n Challenges in the press shop

u Low energy consumption, higher production cycle requirements

u Equipment/employee safety

u Order management and material pulling

n RA solution

u Servo press, high-speed synchronous press, multi-station press

u Comprehensive safety equipment (safety PLC, bus, instructions, etc.)

u Press shop MES system

High Speed Synchronous Digital Press Lin

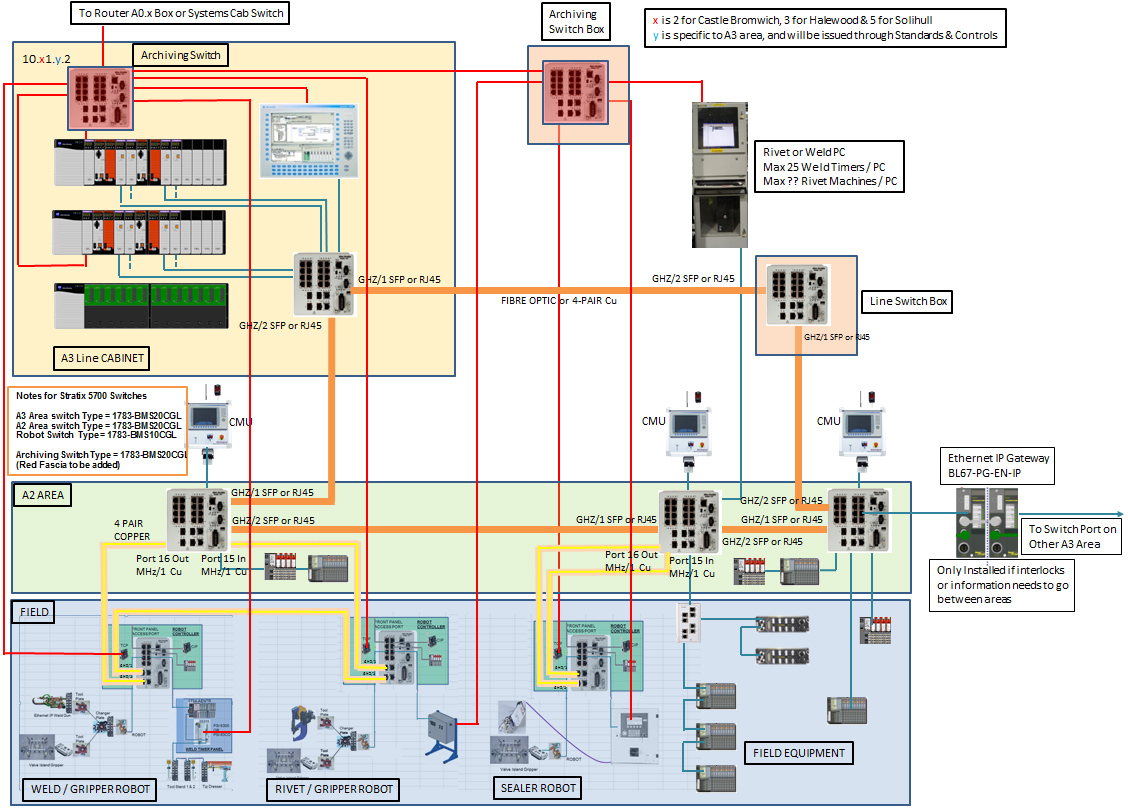

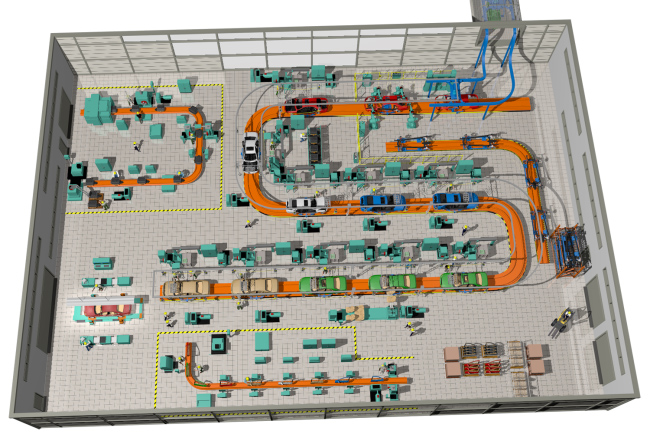

l Body shop application scheme

n Body shop challenges

u Faster model upgrade

u Faster production line speed

u More convenient maintenance

u Safer production environment

n solution

u Advanced transmission based on industrial Ethernet (conveyor line, AGV, etc.)

u Comprehensive IP67 solution

u Comprehensive safety equipment (safety PLC, etc.)

u Body shop MES system

Automatic conveyor line

Automatic feeding line

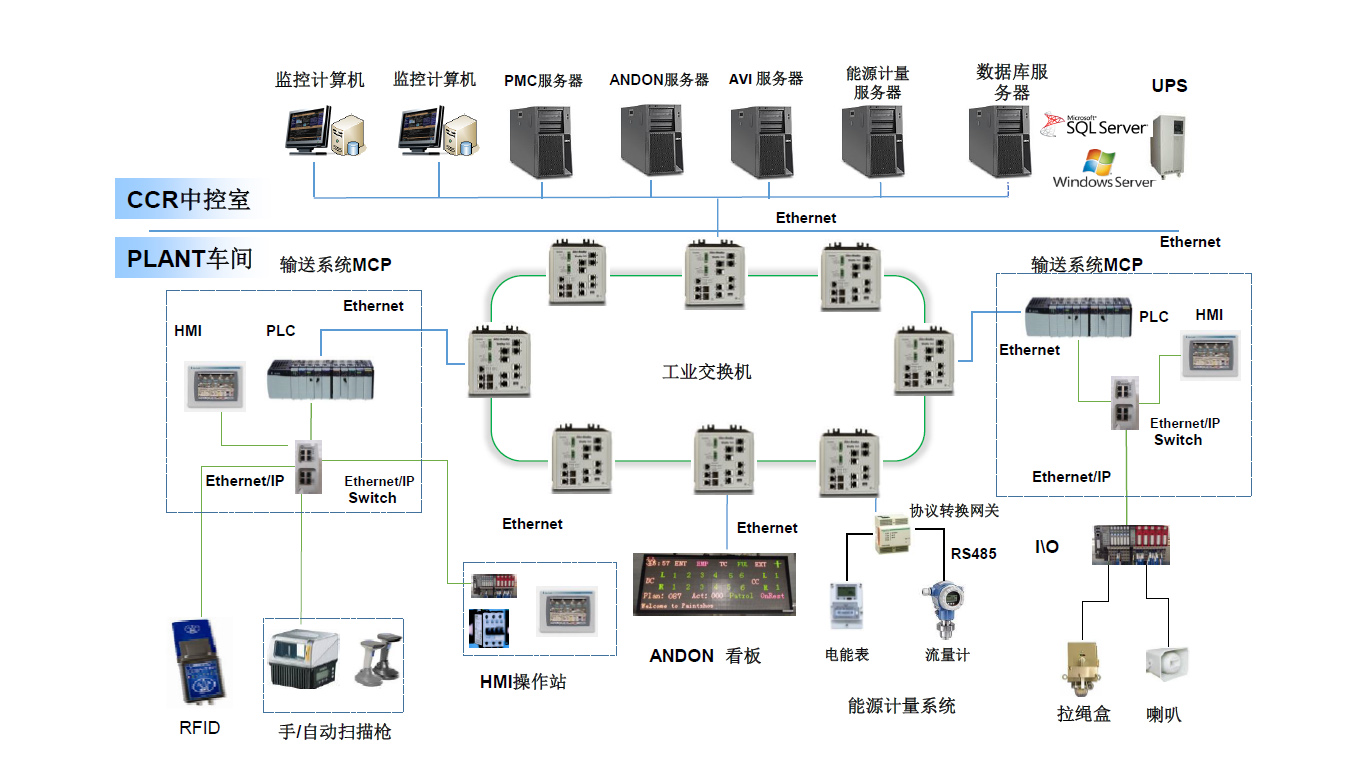

Full Ethernet Architecture for Body Shop

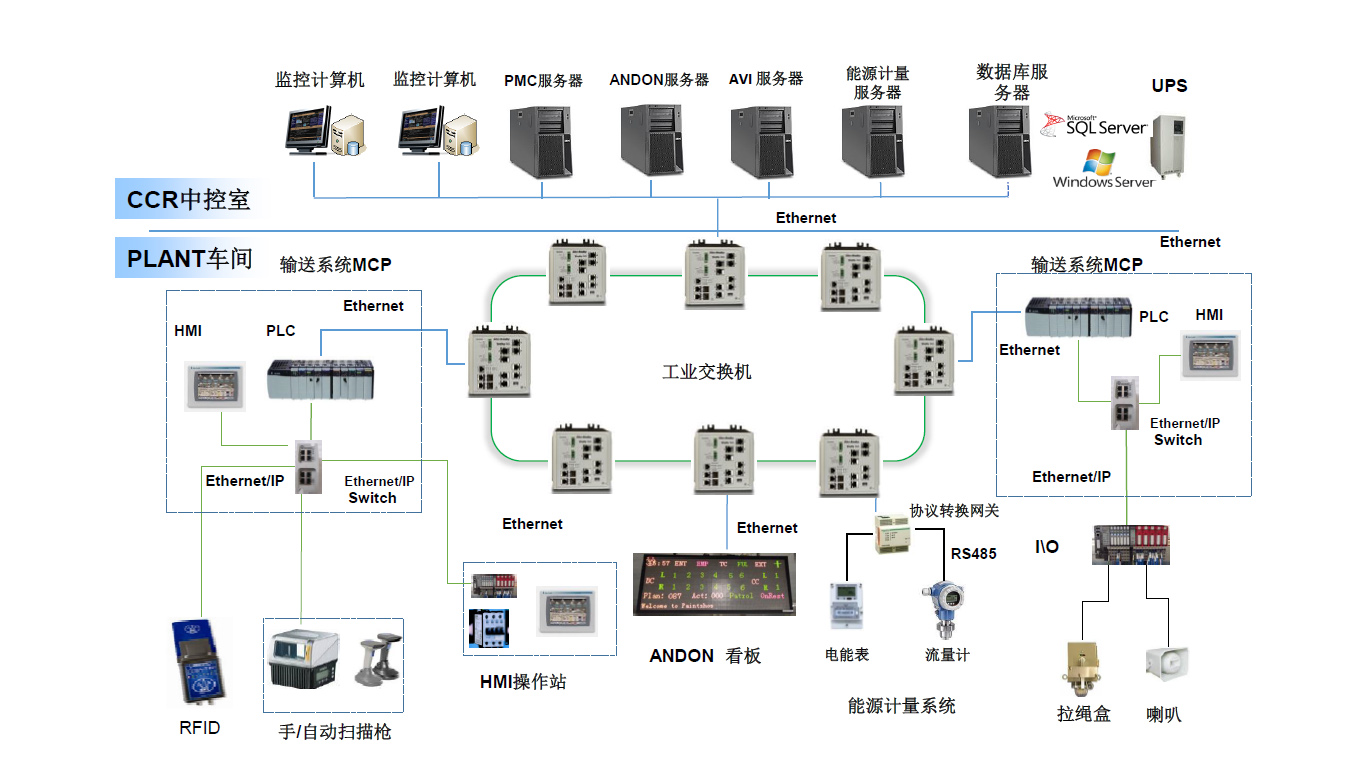

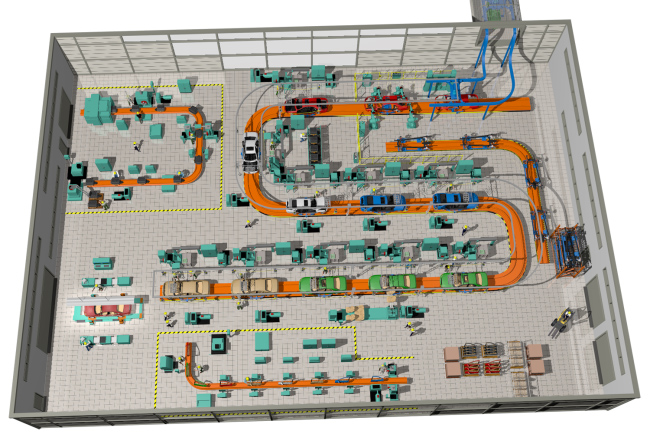

l Application scheme of painting workshop

n Paint shop challenges

u More control methods (discrete, process)

u More similar conveying equipment

u More energy consumption

u Higher environmental and safety requirements

n solution

u A unified platform suitable for various control methods

u Wide range of drive products

u Energy monitoring system and optimal control

u Clean factory control scheme

u Paint shop MES system

l Assembly workshop application scheme

n The challenges of the final assembly shop

u Assembly material pulling and management

u Assembly quality control

u Conveying equipment is complex and diverse

u Pressure of continuous production

n solution

u A unified platform suitable for various control methods

u Assembly workshop material management system

u Assembly workshop quality management system

u Wide range of drive products

Contact Us

Building 6, Ningxing Jiali Plaza, No. 185 Mingxin Road, Yinzhou District, Ningbo City

Tel:( 86-574 ) 87861201

Fax:( 86-574 ) 87861200

Official Account

WeChat Channel

© 2021 JETRON Powered by www.300.cn SEO