An automotive industry

描述

1. Project Background

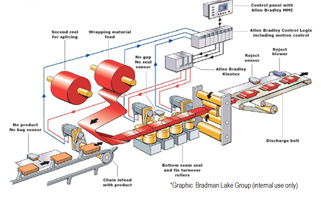

The factory is a high-automation and high-information factory specially built for pure electric vehicles, but the data of each module subsystem, each workshop-level subsystem and a large number of automation equipment are isolated from each other, and comprehensive data analysis cannot be carried out in a centralized manner. Therefore, SAIC Volkswagen hopes to Create a data center to open up various systems and equipment to realize data integration and intelligent analysis.

2. Solutions

Link smart devices and smart meters with MOM's powerful industrial interface engine;

Connect each module system with MOM's powerful interface middleware;

Establish a big data factory smart management system to clean and analyze massive data;

Match enterprise goals, move from manufacturing to intelligent manufacturing, and leverage the future with data.

3. Project value

Case Highlights

(1) Realized data collection of tens of thousands of devices

(2) Realize logistics, intelligent production scheduling, production, quality, equipment, energy, environment, warehousing, vehicle real-time information and other modules, stamping, body, paint, final assembly, battery and other workshops, a total of about 100 systems multi-dimensional billion 10,000-level data access

(3) Give full play to the role of data, deeply mine data, extract key information to users, and realize big data risk early warning

(4) Establish a factory knowledge base, integrate resources, and perform the precipitation and accumulation of knowledge

(5) Establish a plant equipment pedigree tree, and track equipment status in real time

(6) Establish a vehicle intelligent tracking system, and the status of vehicles in production can be queried in real time

(7) Establish a real-time alarm and early warning system, and all workshop alarms and early warnings can be responded to in real time

Achieve results

(1) Each system was successfully connected, data integration was completed, and data utilization efficiency was greatly improved;

(2) The key data of nearly 100 systems can be queried on a single platform, which greatly reduces repeated logins, repeated viewing and data transcription, and time wasted in secondary data processing;

(3) Real-time tracking of production, logistics, quality, monitoring, energy, environment and other data, real-time tracking of vehicle status, real-time alarm status display, real-time storage location status display, real-time AGV status display, forming a digital factory, the viewing system is Can be aware of various states.

Contact Us

Building 6, Ningxing Jiali Plaza, No. 185 Mingxin Road, Yinzhou District, Ningbo City

Tel:( 86-574 ) 87861201

Fax:( 86-574 ) 87861200

Official Account

WeChat Channel

© 2021 JETRON Powered by www.300.cn SEO