JETRON-APC

- Time of issue:2021/10/14

(Summary description)Zhuhai Jie Chuang Huazi Technology Co., Ltd. was jointly established by Jie Chuang Technology and Tsinghua University to jointly develop industrial intelligent control software APC (Jie Chuang based model predictive control algorithm), which is widely used in petrochemical, coal chemical, non-ferrous metals, building materials, etc. industry.

JETRON-APC

(Summary description)Zhuhai Jie Chuang Huazi Technology Co., Ltd. was jointly established by Jie Chuang Technology and Tsinghua University to jointly develop industrial intelligent control software APC (Jie Chuang based model predictive control algorithm), which is widely used in petrochemical, coal chemical, non-ferrous metals, building materials, etc. industry.

- Categories:Automation System Integration

- Author:

- Origin:

- Time of issue:2021-10-14 16:23

- Views:

(1)Jetron based on model predictive control algorithm

Overview: Zhuhai Jetron Huazi Technology Co., Ltd. was jointly established by Jetron Technology and Tsinghua University to jointly develop industrial intelligent control software APC (Jetron Model Predictive Control Algorithm), which is widely used in petrochemical, coal chemical, non-ferrous metals, Building materials and other industries. Jetron's model predictive control algorithm is an indispensable control technology for the optimal operation of the process industry. It can effectively enhance the anti-interference ability and process constraint processing ability of plant production, improve the stability of plant operation, and reduce production fluctuations and the intensity of human intervention. , through the realization of "card edge operation" to fully excavate the process and equipment capabilities of the device, thereby helping customers to obtain maximum economic benefits.

Feature:

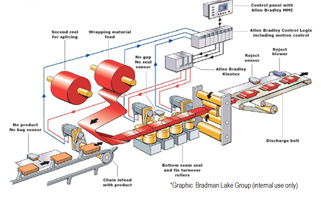

MES (Manufacturing Execution System) is the focal point for the planning and implementation of digital smart factories, and it is also the core and key to the construction of digital smart factories. MES is a production information management system oriented to the workshop executive layer. It is connected to the ERP system on the top and PLC program controllers, data collectors, barcodes, testing instruments and other equipment on the site.

The construction of Jetron MES is achieved through the following aspects:

Factory Modeling - Digitally mapped factory modeling (factory, workshop, section, process)

· Equipment networking - industrial workshop Ethernet planning and construction, various intelligent equipment networking communication implementation

· Production Scheduling - APS Advanced Production Scheduling

· Plan release - release of production tasks and plans, release of relevant process standards and drawings

· Workshop logistics - supply of various materials required for production, organization of tooling and molds

· Data collection - man-machine material method data collection in the whole manufacturing process (production master data, quality information, equipment data, energy data), SCADA system construction to realize automatic equipment collection

· Statistical analysis - statistical analysis of production big data, SPC analysis, presenting multi-angle statistical analysis results by theme

· Process control - abnormal warning, product map, production traceability, on-site visualization, monitoring center, mobile APP

· Integrated management - production, quality, equipment, energy

Scan the QR code to read on your phone

Contact Us

Building 6, Ningxing Jiali Plaza, No. 185 Mingxin Road, Yinzhou District, Ningbo City

Tel:( 86-574 ) 87861201

Fax:( 86-574 ) 87861200

Official Account

WeChat Channel

© 2021 JETRON Powered by www.300.cn SEO