Automation Control System

- Time of issue:2021/10/14

(Summary description)The PlantPAx® system provides an advanced distributed control strategy. The system shares a common technology (Integrated Architecture® system) with all other automation applications in the plant. This strategy builds a seamless flow of information plant-wide to provide optimization opportunities and enable the Connected Enterprise.

Automation Control System

(Summary description)The PlantPAx® system provides an advanced distributed control strategy. The system shares a common technology (Integrated Architecture® system) with all other automation applications in the plant. This strategy builds a seamless flow of information plant-wide to provide optimization opportunities and enable the Connected Enterprise.

- Categories:Automation System Integration

- Author:

- Origin:

- Time of issue:2021-10-14 16:23

- Views:

The PlantPAx® system provides an advanced distributed control strategy. The system shares a common technology (Integrated Architecture® system) with all other automation applications in the plant. This strategy builds a seamless flow of information plant-wide to provide optimization opportunities and enable the Connected Enterprise.

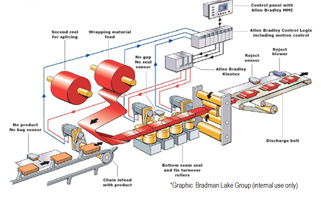

The PlantPAx system is based on open industry standards and utilizes the EtherNet/IP network as its backbone. EtherNet/IP networks help support seamless integration of system components and connections to advanced business systems. PlantPAx systems support EtherNet/IP and ControlNet™ networks for device-level communications, delivering business solutions with real-time results from the bottom of the shop floor to the top

In process automation, securing critical operations requires extreme engineering to ensure no components are lost, stopped working, or damaged. This professionalism often involves implementing highly available automated systems. The PlantPAx platform enables high availability by providing redundancy options at all layers of the architecture. You can choose the level of redundancy you need without having to buy redundant components that you don't need.

Efficient overall solution

PlantPAx is the only process automation system capable of managing automation applications in multiple domains, including motion, safety, and drive systems. Through the powerful combination of the scalability of the PlantPAx system and Rockwell Automation's domain expertise, you can use plant-wide production information technology to identify production problems in real time, helping you respond to market demands quickly and cost-effectively.

1、Engineering and Configuration

Helps reduce development time and minimize human errors

Unified Engineering Design Environment

• Save time by calling various system configuration tools from a unified platform for database management and large-scale system engineering

Modular Object Library

• Co-development and configuration of logic and HMI objects reduces development time

Well-defined system architecture

• Minimize the risk of unreasonable system structure and ensure system performance

2、Control and I/O

Offers the most popular architectures for the most cost-effective designs Scalable controller portfolio

• Supports integrated process installations ranging from ten to thousands of points

Stable and reliable network architecture

• EtherNet/IP with extensive use of CISCO® technology and redundant options at every network level for exceptional performance

wide openness

• Supports common legacy I/O and smart devices

3、Safety and Critical Controls

Reduce your economic risk by protecting critical assets

Process control with high availability

• From redundant I/O to redundant controllers, from scalable networks to redundant HMI servers, providing high-availability solutions

Scalable process safety

• Integrated Basic Process Control System (BPCS) and scalable SIS solution including Triple Modular Redundancy (TMR) for maximum availability

4、operator efficiency

Helps improve operator efficiency with at-a-glance process information

Integrated visualization

• Provides intuitive displays, objects and faceplates, plus integrated diagnostics for faster operator response

Alarm and Event Management

• Integration into unified alarm information

decision support tool

• Graphical panels help operators optimize operations

Extensible Architecture

• Traditionally configured or simulated for process, mobile and stand-alone applications to large distributed control systems Asset management and system maintenance Improve asset management efficiency and predictive maintenance to ensure plant uptime

meter

• Comprehensive equipment management that meets industry standards

Electrical Equipment

• Frequency converters and smart motor control devices as integral components

5、Batch management and control

Ability to respond flexibly to external requirements such as compliance, yield optimization and production flexibility

Extensible Platform

• Integrated batch solutions from cell scale to highly complex

Compliant with ISA-88 structure

• Simplify change management and compliance

Integrated Analysis Tools

• Provide batch reporting, material tracking, traceability and other comprehensive solutions to optimize batch production

6、Efficient operation

Quickly deliver real-time information to managers

Flexible data collection solutions

• Provide local control-level, factory-level or enterprise-level historical data storage function, collect and store data in real time

Decision Support Toolkit

• Track key production indicators (KPIs), manage cost, quality and resource consumption to help optimize operations

7、Advanced Process Control

Provides reliable economic benefits by increasing yields, reducing costs, improving product quality and reducing the risk of environmental contamination

Broadest portfolio of solutions

• From basic regulatory control to fuzzy logic, from soft instrumentation to model predictive control, all-encompassing and flexible optimization solutions

• Plant-wide optimization down to the single loop in the controller, up to the supervisory level

8、corporate security

Address security risks and help protect people, assets and information from unexpected or potential threats

Safe and reliable operation

• Control system architecture with layered protection helps maintain operational integrity in the presence of disturbances

Asset and Information Protection

• Product and system features applied to control access and limit disclosure of information

Compliant with industry norms

• Provide an open control system that conforms to international standards

Scan the QR code to read on your phone

Contact Us

Building 6, Ningxing Jiali Plaza, No. 185 Mingxin Road, Yinzhou District, Ningbo City

Tel:( 86-574 ) 87861201

Fax:( 86-574 ) 87861200

Official Account

WeChat Channel

© 2021 JETRON Powered by www.300.cn SEO