A sewage upgrading and renovation project

描述

1. Project Background

This project is the upgrading and renovation project of the first, second and third phases of a sewage treatment plant. The first and second phases of Dataansha mainly treat urban sewage in Liwan District, Yuexiu District and Baiyun District (parts) (including Shijing River, Liwan Chung, Si Ma Chung ( Aokou Chung) and other important river basins); the water collection range of Dataansha Phase III is bounded by Xinguangcong Road and Dajinzhong Road in the east, Huangshi Road in the north, and the Pearl River West Channel in the west. It is bounded by the shore, and bounded by the Huancheng Expressway in the south, including Tongdewei Community, Luoyongwei, Datansha Island, Jinshazhou, etc. to the south of the Huancheng Expressway. The scale of the first, second and third phases of the sewage treatment plant is 550,000 m3/d.

This project has been completed and put into operation on January 10, 2020. The first, second and third phase of the sewage treatment plant will be upgraded to a level not lower than that of the Guangzhou Municipal Water Affairs Bureau. "Han Sui Shui Han" [2017] No. 20, "Urban Sewage Treatment Plant Pollutant Discharge Standard" Class A Standard, Guangdong Provincial Local Standard "Water Pollution Discharge Limit" (DB44/26- 2001) the stricter value of the first-level standard and the surface V-class water (and above) standard, further reducing pollutants, and meeting the effluent discharge standard of the sewage treatment plant.

2. Solutions

• Added secondary filter process

• Increased filter capacity

• Precise aeration, refined management

Process introduction

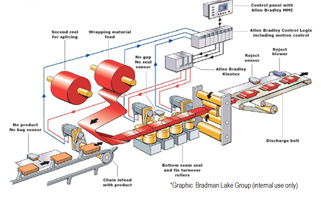

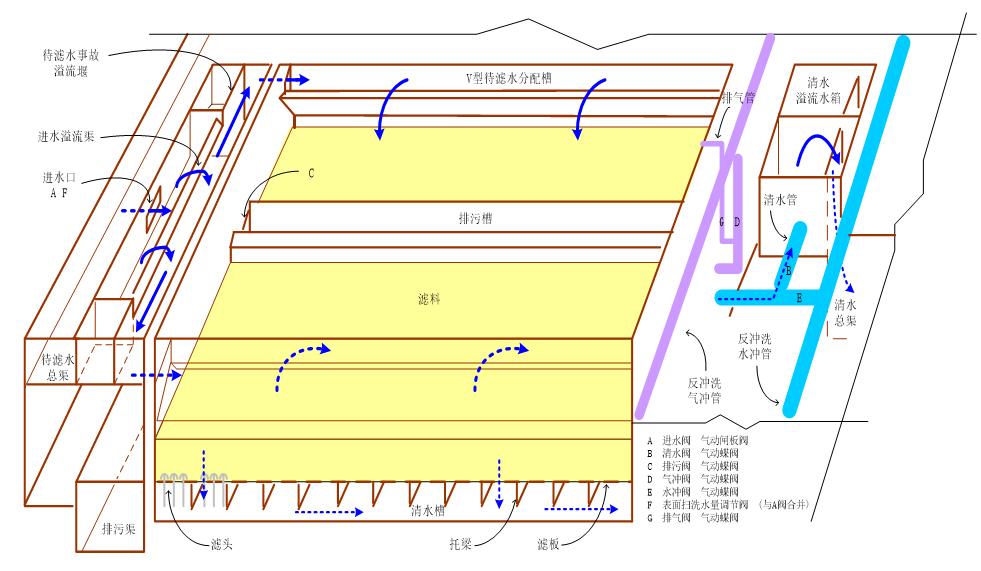

1. V-type filter is a kind of gas-water backwashing fast filter, and its technological process is as follows:

Secondary effluent → V-type filter → disinfection measures → effluent

Schematic diagram of the V-type filter process flow

(1) Filtration process

After the water to be filtered passes through the water inlet valve and the square hole from the main water inlet channel, it overflows through the weir mouth, and then enters the V-shaped groove along the side hole which is flooded by the water to be filtered. filter. The filtered water filtered by the homogeneous filter layer flows into the bottom space through the long-handled filter head, and enters the gas-water distribution pipe channel through the square hole.

(2) Backwashing process

The V-type filter tank is backwashed by air and water, which is divided into single-air flushing. The air with the strength of about 55 m3/m2•h makes the sand layer boil and scrub in an all-round way without expanding, so that the entire filter tank is not inflated. There may be dead corners of sludge accumulation, and then the gas and water are flushed at the same time, the material layer is slightly expanded, and the sludge in the sand is surfaced by the backwash water with a small flow (about 10m3/m2•h) while the gas is scrubbing. The filter layer is rinsed with 17m3/m2•h strength water until the filter layer is completely clean. Finally, the deceleration filtration technology is adopted. During the whole backwashing process, the side water flow out of a V-shaped groove will flush the scum on the backwashing surface to the center. Drainage, air distribution and water distribution use long-handled filters.

3. Project value - production effect

(1) Single air washing stage: Loosen the entire filter layer, and the dirt that is not easy to peel off during water washing can be peeled off under the high shear force of the sharp rise of air bubbles;

Air wash stage live map

(2) Air-water combined flushing stage: the air flushing intensifies the collision and friction between the filter material particles. During water flushing, the shearing effect on the surface of the filter material particles can also be fully exerted, which strengthens the water flushing efficiency;

Live map of gas-water combined washing stage

(3) Water flushing: Single water flushing takes the fallen impurities out of the filter material layer.

Live view of the water flushing stage

Contact Us

Building 6, Ningxing Jiali Plaza, No. 185 Mingxin Road, Yinzhou District, Ningbo City

Tel:( 86-574 ) 87861201

Fax:( 86-574 ) 87861200

Official Account

WeChat Channel

© 2021 JETRON Powered by www.300.cn SEO