Chemical Group Co., Ltd. - Equipment Management

描述

1. Case overview

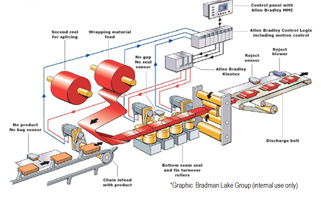

Based on the full-process production process of phosphate fertilizer, the construction of the phosphate fertilizer full-process manufacturing execution system (hereinafter referred to as "P-MOM") aims to provide customer-oriented product services and realize intelligent manufacturing of product series in the phosphate fertilizer industry.

2. Case application background

The equipment management of P-MOM can connect the equipment management departments of the whole plant, achieve data sharing, and form a complete equipment management system. In the company, the management of production equipment maintenance/overhaul/point inspection plan, the collection and management of equipment inspection data and equipment operation data, and equipment report management are realized.

3. Case innovative experience

Through the production information integration platform, various important parameters of the daily operation of the company's key production equipment are collected in real time, and the parameters of the production equipment operation and the data of daily inspection are automatically summarized. On this basis, according to the formula of the system configuration, the statistical data such as equipment integrity rate, utilization rate, equipment efficiency, equipment accident, etc., as well as the calculation function of various indicators of equipment operation are automatically completed. Calculate data based on summary data and various indicators, and automatically generate and provide relevant equipment operating ledger/reports. In the tracking of equipment operation status, according to the summary logic, the parameters of production equipment operation and the data of daily inspection are automatically summarized, the performance of equipment operation is analyzed online, and displayed in the form of charts; Prepare equipment maintenance plans and spot inspections, inspections, lubrication, and leak-free plans, and provide input and storage functions for recording previous equipment maintenance; based on the work flow set by the system, realize the tracking of equipment maintenance plans and implementation; based on maintenance plans Content, realize maintenance work order management.

4. Results of case application

Through the production information integration platform, various important parameters of the daily operation of the company's key production equipment are collected in real time, and the parameters of the production equipment operation and the data of daily inspection are automatically summarized. On this basis, according to the formula of the system configuration, the statistical data such as equipment integrity rate, utilization rate, equipment efficiency, equipment accident, etc., as well as the calculation function of various indicators of equipment operation are automatically completed. Calculate data based on summary data and various indicators, and automatically generate and provide relevant equipment operating ledger/reports. In the tracking of equipment operation status, according to the summary logic, the parameters of production equipment operation and the data of daily inspection are automatically summarized, the performance of equipment operation is analyzed online, and displayed in the form of charts; Prepare equipment maintenance plans and spot inspections, inspections, lubrication, and leak-free plans, and provide input and storage functions for recording previous equipment maintenance; based on the work flow set by the system, realize the tracking of equipment maintenance plans and implementation; based on maintenance plans Content, realize maintenance work order management.

Contact Us

Building 6, Ningxing Jiali Plaza, No. 185 Mingxin Road, Yinzhou District, Ningbo City

Tel:( 86-574 ) 87861201

Fax:( 86-574 ) 87861200

Official Account

WeChat Channel

© 2021 JETRON Powered by www.300.cn SEO