Application case of smart factory in aluminum industry

描述

1. Solution background

With the continuous acceleration of informatization and the vigorous development of 5G technology, the traditional aluminum industry has also

suffered a huge impact.

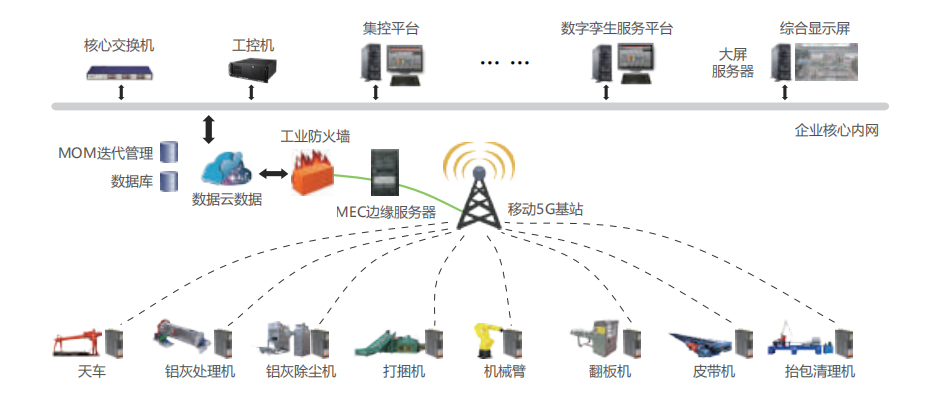

This solution helps a company in the aluminum industry build a smart factory, improves the company's competitiveness in the market, and realizes a digital twin.

Based on 5G network, combined with MEC edge cloud technology, remote monitoring, intelligent detection and edge control applications based on edge computing technology are carried out through JENET 5G industrial gateway.

2. Analysis of solution requirements

Due to the strong electromagnetic interference of the on-site environment, the untimely monitoring of on-site equipment, the imperfect fault alarm system, and the imperfect information platform of an aluminum industry enterprise, the production and operation activities of the enterprise are seriously affected.

According to the above requirements, the problems to be solved by this solution are as follows:

1. Due to the weak support and obvious shortcomings of the information platform system currently used by the enterprise, the enterprise needs to carry out digital transformation to realize the status monitoring of the underlying equipment and ensure the production progress;

2. Due to the strong electromagnetic interference of the company's unique electrolytic aluminum workshop, ordinary communication equipment cannot work in a strong electromagnetic interference environment. The company needs to introduce equipment with strong anti-electromagnetic interference ability to ensure data transmission and reduce production costs;

3. According to the internal production and operation plan of the enterprise, the production site has many different types of PLC corresponding to many different communication protocols. It is necessary to adapt to various types of communication protocols to collect data from PLC. Therefore, the gateway device is required to support reading of multiple communication protocols. ;

4. According to the industrial on-site investigation of the enterprise, the underlying equipment of the enterprise has a high working intensity and the fault alarm system is not perfect. It is necessary to monitor the status of the on-site equipment, realize the fault early warning, and ensure the stability of the equipment operation. Due to the scattered points of the on-site equipment, it is difficult to achieve centralized data management. , With the help of 5G low-latency, large-bandwidth, and high-speed characteristics, data collection is carried out for each part of the equipment, and the equipment status is analyzed according to the data to realize equipment status monitoring.

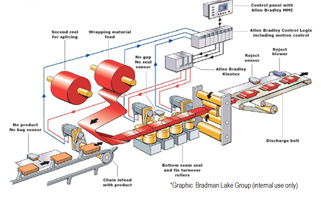

3. Solution system diagram

4. System function

• Support PC-side management of the system

• Communication protocol: support access to various mainstream protocols

• Monitoring large screen: 24-hour uninterrupted monitoring of the operation status of each equipment in the park and the production efficiency of each equipment through the large screen

• Device management: support device addition, configuration and establishment of device files

• Fault alarm: Support equipment fault alarm. When the equipment fails, the PLC will transmit the point change to the platform, and the platform will notify the corresponding person in charge by telephone or other means

• Data collection: Support AB, Siemens and other types of PLC data collection, transmit the point information in the PLC to the database in 5G mode, and transmit the data in the database to the digital platform

• Log Recording: Support the recording of historical data, historical alarm information, historical device online and offline and other data information of the device

• User management: Supports user classification and role-based management in the system

5. Achieving goals

• Since the 5G gateway has strong electromagnetic field anti-interference ability, it can effectively solve the interference problem of equipment data collection in strong magnetic field environment

• Through the 5G gateway to adapt to a variety of different protocol types PLC, the data of each PLC can be collected and uploaded to the control platform

• Real-time data transmission through 5G wireless network, the control platform can remotely monitor the operation status of the equipment, without the need for on-site inspections

• Realize early warning of equipment failure, and timely feedback to mechanic personnel for quick response maintenance when equipment fails

• Through remote monitoring, it saves time for troubleshooting and improves production efficiency

6. System Features

Centralized maintenance

• See the travel status of all devices at a glance

• Centralized management of devices

Precise positioning

• In the event of a failure, the dispatch center determines the area where the equipment is located as soon as possible

• Notify the mechanics in time according to the fault point information fed back by the data

Overall coordination

• Through the operation status of the equipment, coordinate the production of the whole plant and effectively improve the production

• efficient

Contact Us

Building 6, Ningxing Jiali Plaza, No. 185 Mingxin Road, Yinzhou District, Ningbo City

Tel:( 86-574 ) 87861201

Fax:( 86-574 ) 87861200

Official Account

WeChat Channel

© 2021 JETRON Powered by www.300.cn SEO